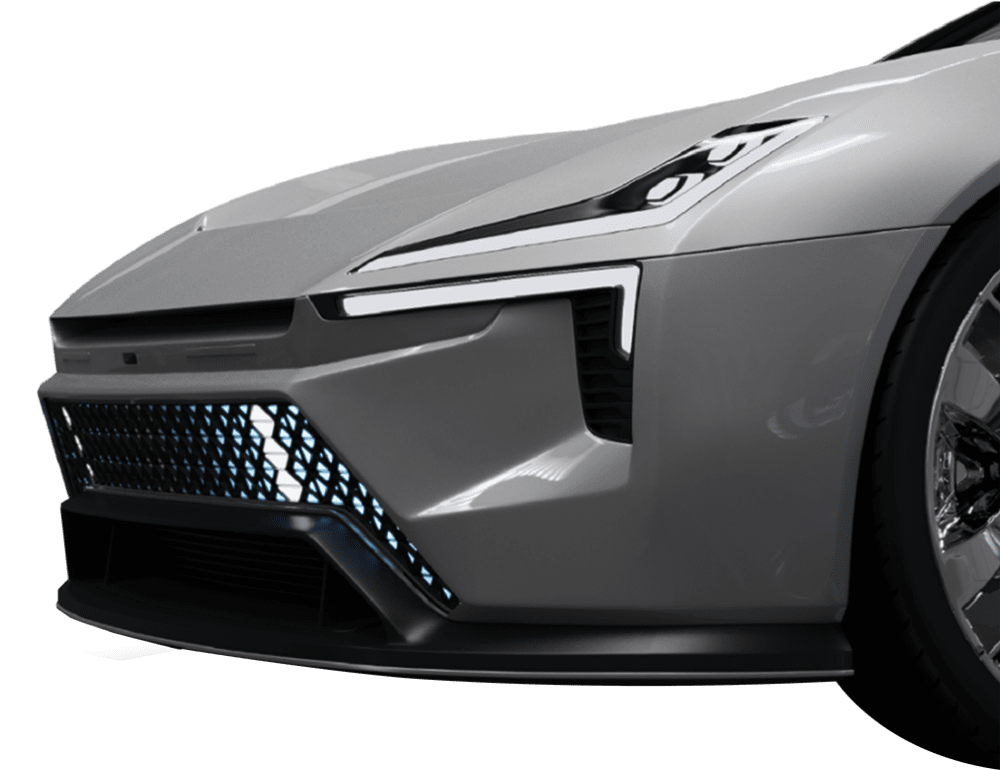

Automobile

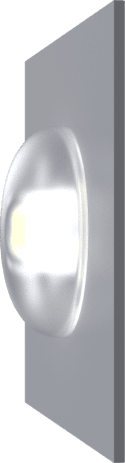

Silicone lens

LED light

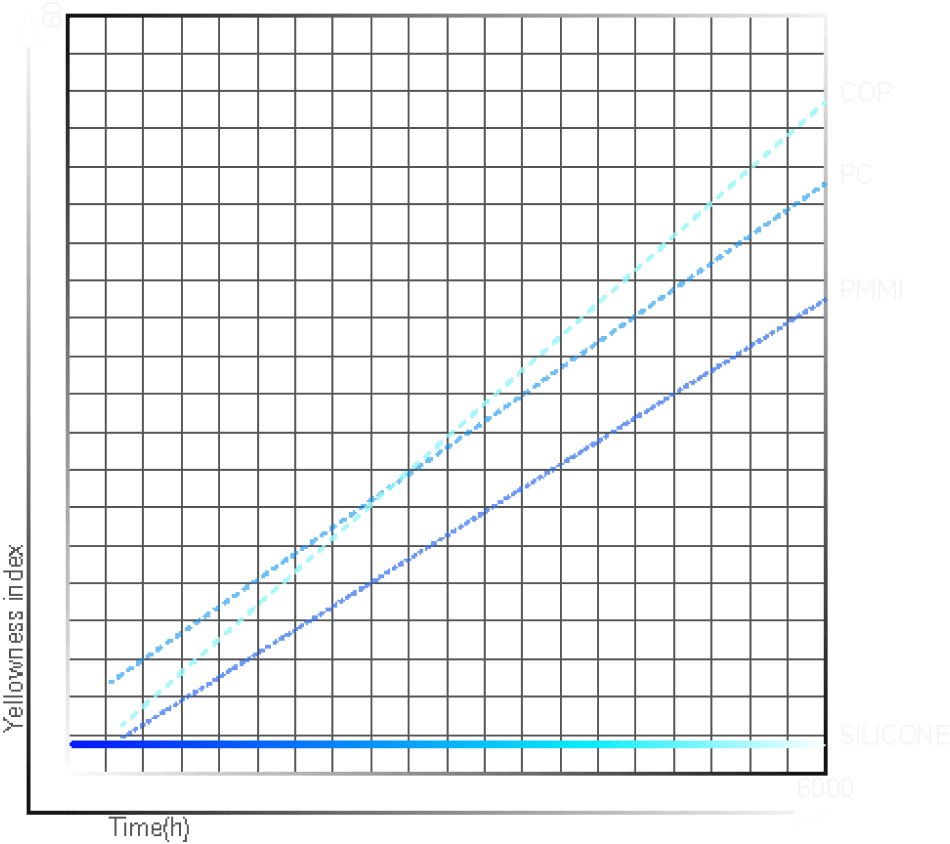

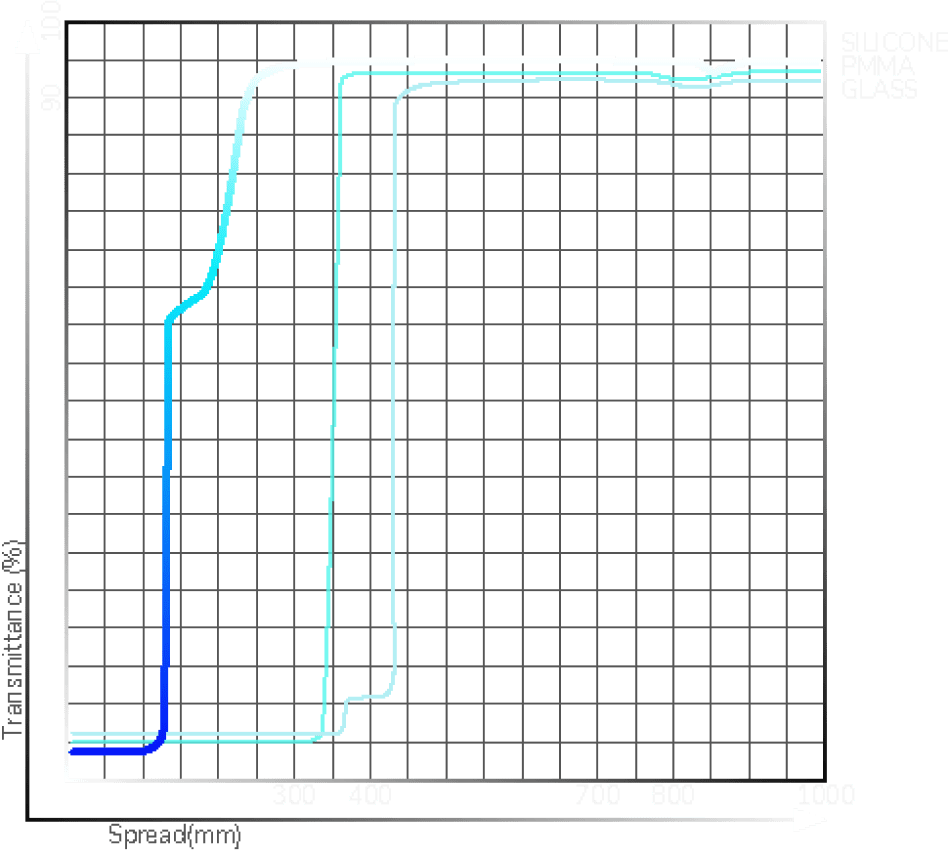

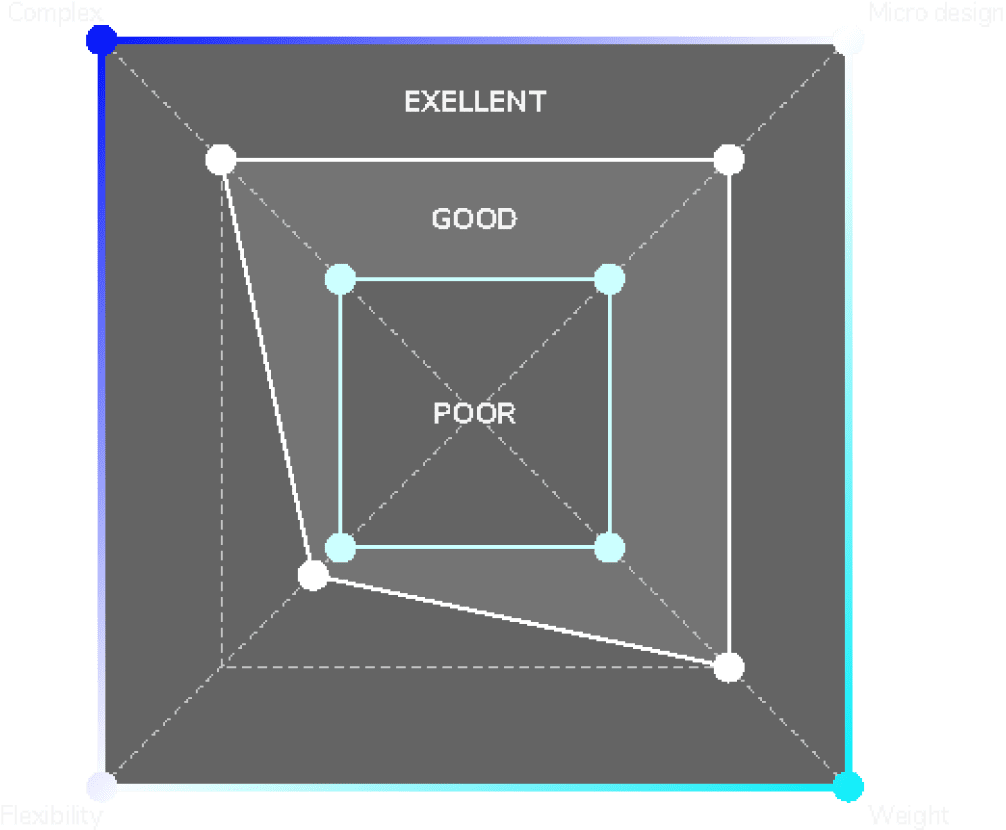

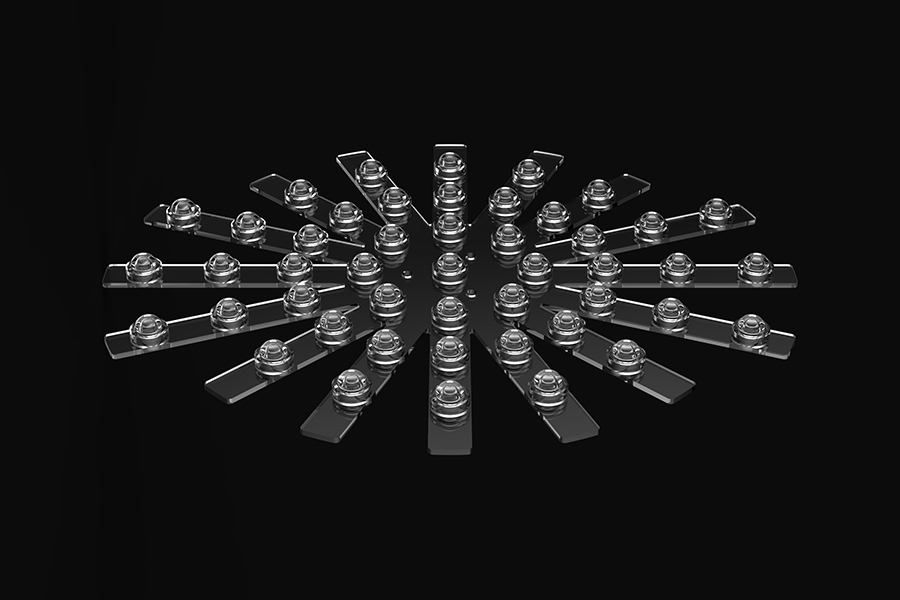

Silicone Lens

Healthcare

Silicone lens

Other

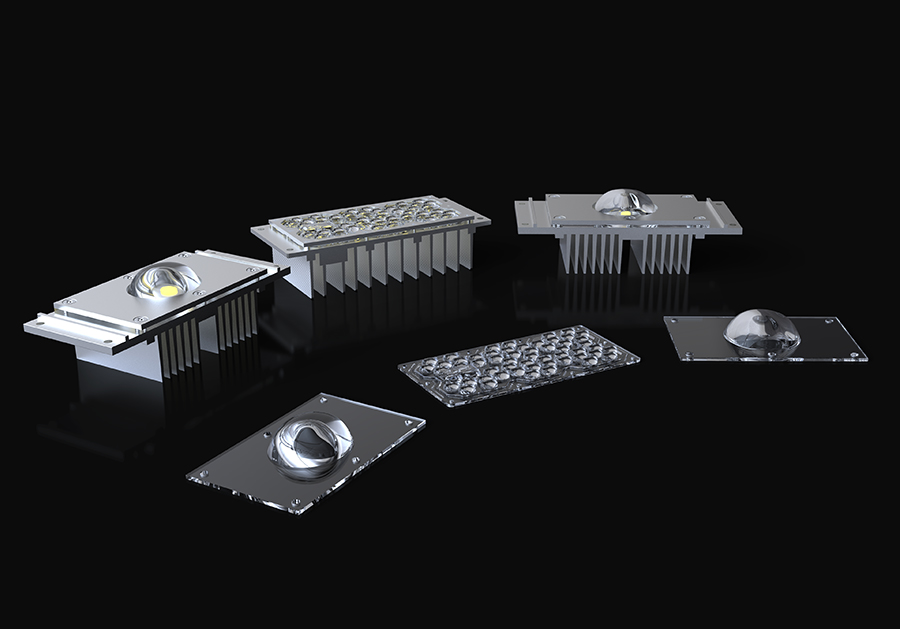

Products

-

- Kailux

- AIoT smart lighting platform : A group of experts providing one-stop solutions for indoor and outdoor lighting

-

- INNOSAVER

- The world's only wireless automatic power saving system that dramatically reduces electrical energy with wireless multi-sensor and human body detection algorithm technology

-

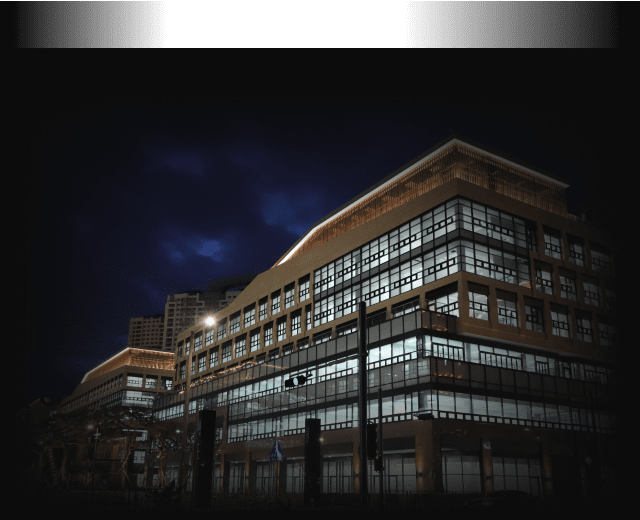

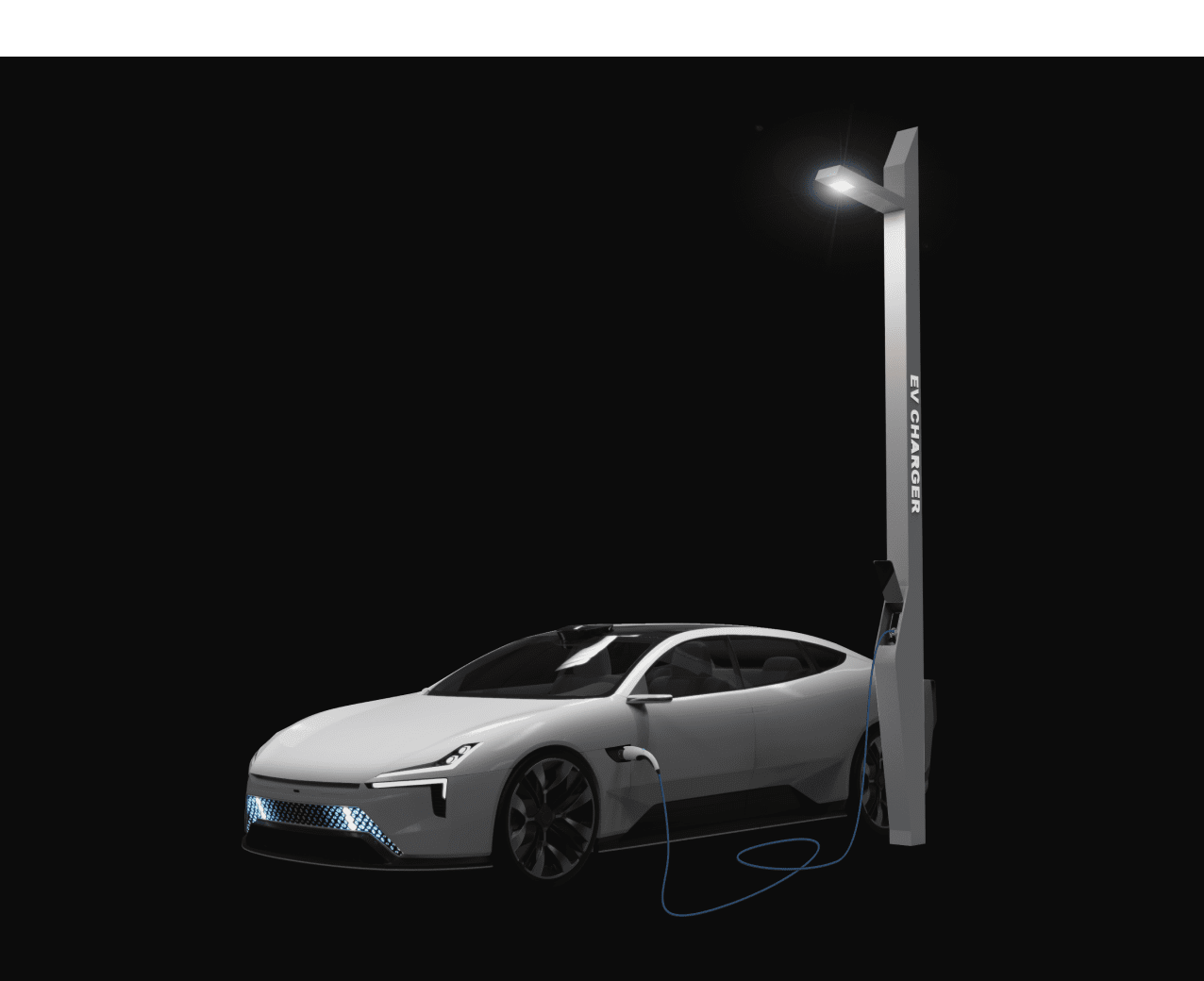

- EV charging streetlight

- Slow charging streetlight system for electric vehicles using streetlights in general roads or residential areas